Zinc alloy material quality decides the brightness of product.

We use zinc alloy #3 which is with good characteristics for making various gifts & premiums and accessories, and it meets international standard. Good zinc alloy material is stable when die casting, and the finished product looks brighter.

Mold design influences the product performance.

We aim to fully realize your ideas on the final products, so we have professional mold design team. We are especially good at 3D engraving.

Practiced die casting skill makes high yield rate.

Die casting is a complex skill, relating to fluidity and heat. We have been in this industry for many years and keep advancing our skills. Some products need waterflow cooling system in the mold to avoid quality change due to the temperature difference during injection.

Refined polishing and grinding

Delicate polishing makes fine products.

We remove the burrs on the raw models by different ways to make perfect and high value products.

Semi-automation obtains stable quality.

For polishing, we use semi-automation machine to make all products at the same standard and keep the stability.

Plating is the costume of product

Rack plating keeps good product appearance.

There’s a certain distance between each product on the plating rack, so products won’t knock against each other, and the plating color will be even on the whole product and each product.

Plating contents decide product finish color.

We use high purity and eco-friendly plating contents to make strong and durable finish.

Stable workmanship

Strict quality control for your brand.

We know the goods from our factory represent your company image, so we keep close tabs on every manufacturing process to keep the quality.

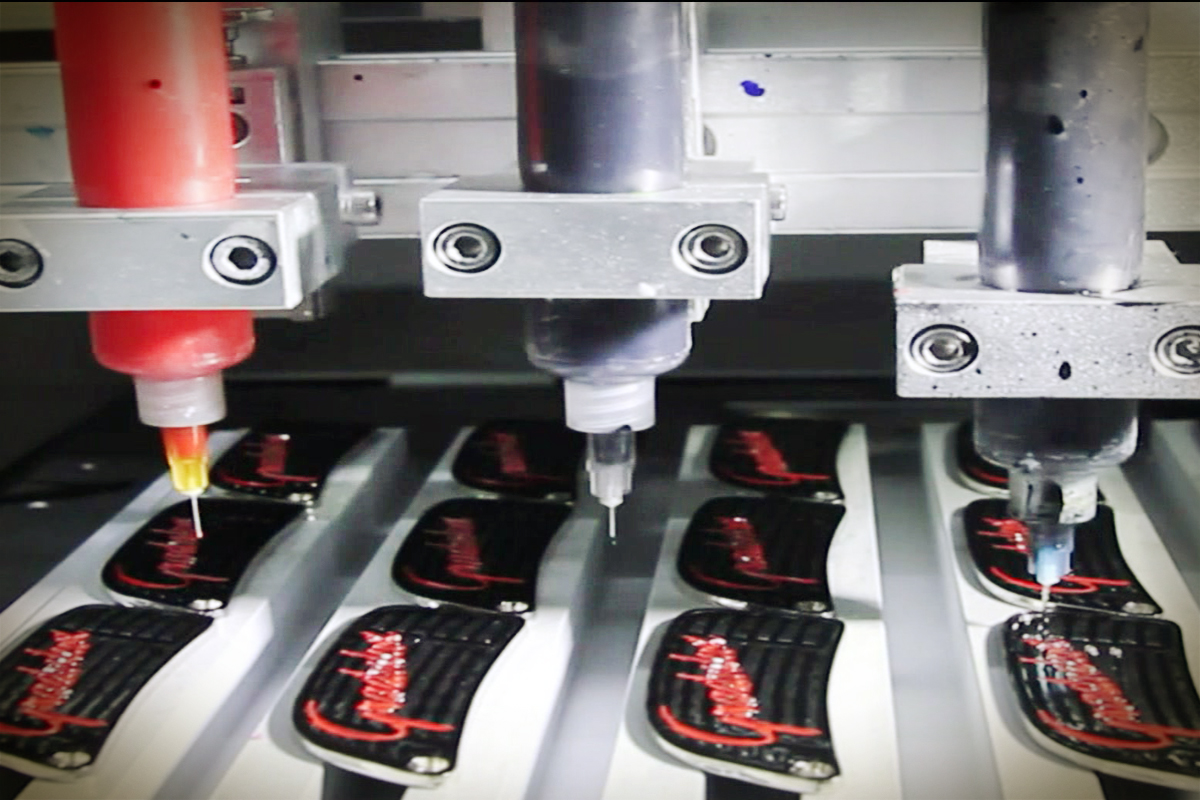

Automatic coloring makes better products.

To speed up the production time and keep stable quality, we equipment with automatic coloring machines to do faster and more detailed coloring.